Raising Water Consciousness through

World’s Biggest Photo Exhibition and

Largest collection of Photo Stories on Water

Photo Stories | Water and EnvironmentA story based on the theme of World Water Day 2017

Best Practices in Blackwater Management: The Case of Sulabh International

Nandita Singh and Om Prakash Singh

29 May 2017

Blackwater is the wastewater containing feces, urine and flushwater from flush toilets along with anal cleansing water or other organic cleaning material. Blackwater poses significant water quality problems due to high content of nitrogen, phosphorous and potassium as well as presence of harmful pathogens like bacteria, mold, and viruses that can cause serious health problems. As a result, blackwater management presents significant challenges. In urban India, the most common practice for managing blackwater entails mixing it with grey water (that comes from washing, cleaning, bathing and other domestic uses) in centralized municipal sewage systems. However, sewage treatment plants (STPs) that help manage the centralized sewage so collected exist only in few cities and towns, and even in these, many colonies remain unconnected. Further, the operational efficiency of STPs is generally low due to power cuts or infrastructural breakdowns, capacities are insufficient, and nutrients and contaminants often leak into the environment through damaged sewer networks. Among decentralized options, stand-alone septic tanks that just serve to collect the blackwater are also unsustainable because there exist no facilities for treating the extracted wastewater. All these limitations lead to the release of large quantities of untreated blackwater directly into surface water bodies as well as its leaching into groundwater aquifers. Pit latrines are a good decentralized option where the blackwater is treated in-situ to produce manure. However, these may also pose the risk of contaminating water sources if located close by. Given these drawbacks and limitations facing the conventional blackwater treatment systems in use in India, a sustainable way forward is the decentralized integrated blackwater management system pioneered and practiced by Sulabh International Social Service Organisation. In this system, blackwater from the toilets is first collected and treated in an on-site anaerobic digester for biogas production. The emergent effluent is next recycled to remove color, odor and pathogens to make it available for multiple non-potable reuses. This photo story aims to illustrate Sulabh’s innovative practice, highlighting the processes involved and their multiple utilitarian byproducts. The title photo depicts the Sulabh effluent treatment (SET) plant that recycles the wastewater emerging from biogas digesters at the community toilet -cum-bath complex in Shirdi, Maharashtra near the holy shrine of Shri Sai Baba.

Sulabh's community toilet-cum-bath complex in Shirdi, Maharashtra

Sulabh International Social Service Organisation, popularly known as Sulabh, is a non-profit voluntary organisation founded in 1970 by Dr. Bindeshwar Pathak. It is well-recognized nationally and internationally for its innovations and practices in the fields of sanitation, liberation of manual scavengers, social transformation of society, environmentally sustainable wastewater management and development of non-conventional sources of energy. Construction and maintenance of toilets at public places and in informal colonies on 'pay and use basis' is a landmark of Sulabh and so far it has constructed and is maintaining over 8000 such public toilets in India. These public toilets have helped liberate over a million scavengers from the task of manually cleaning the toilet pits in over 640 towns, instead providing them alternate employment. For the untiring efforts, its founder Dr. Pathak has been honored with a number of awards nationally as well as internationally, including the prestigious Stockholm Water Prize in 2009.

Public using Sulabh's toilet-cum-bath complex in Shirdi, Maharashtra

Spread over an area of two acres and usable by approximately 30,000 visitors on a daily basis, Sulabh's community toilet-cum-bath complex at Shirdi is the world's largest toilet and bath facility. This 'pay and use' facility consists of 120 WCs, 28 special toilets, 108 bathing cubicles, six dressing rooms, and also urinals and 5000 safety lockers for visitors. It possesses its own biogas plants and SET plant for recycling the blackwater generated in the complex.

Women and girls using the ladies' toilet block in the toilet-cum-bath complex at Shirdi, Maharashtra

There exist separate toilet blocks for women and men in the Sulabh toilet complexes. Due to the large number of pilgrims and tourists regularly visiting Sai Baba's shrine in Shirdi, both the toilet blocks here have a large number of users on a daily basis.

Drains from the toilets leading towards the biogas digesters at the toilet-cum-bath complex in Shirdi, Maharashtra

The drains from individual toilets at the Shirdi complex converge into a common outlet that conveys the blackwater across to 3 biogas digesters installed within the premises.

Biogas digester at the toilet-cum-bath complex in Shirdi, Maharashtra

The majority of the biogas digesters in the Sulabh toilet complexes are fixed dome units with capacity ranging from 30-60 cubic metres (cum) serving public toilets for 500-5,000 users per day. The digesters are built underground into which excreta from all the public toilets in the complex get discharged under gravity. At the Shirdi complex, all the three digesters are operational round the year, requiring desilting once in 2-3 years. Inside the digester biogas is continuously produced due to anaerobic fermentation with the help of methanogenic bacteria. The biogas thus produced is stored in an inbuilt liquid displacement chamber at the top of the dome. It is estimated that about one cubic foot (cft) biogas (approx. equivalent to 0.03 cum) is produced from the human excreta of one person per day. The biogas contains about 65% methane, 32-34% carbon dioxide and hydrogen sulphide and other gases in traces. The design developed by Sulabh does not require any manual handling of human excreta and there is complete recycling and resource recovery from the wastes.

A mantle lamp lighted by biogas at the toilet-cum-bath complex in Shirdi, Maharashtra

The biogas generated in the digester can be put to different kinds of consumptive uses. At the Shirdi complex, it is used directly for lighting mantle lamps, which consume 2-3 cft gas per hour per lamp, having illumination capacity equivalent to 40 watt electric bulb at 220 volts. Biogas-powered mantle lamps can be a useful source of light especially in areas where power supply is absent or poor.

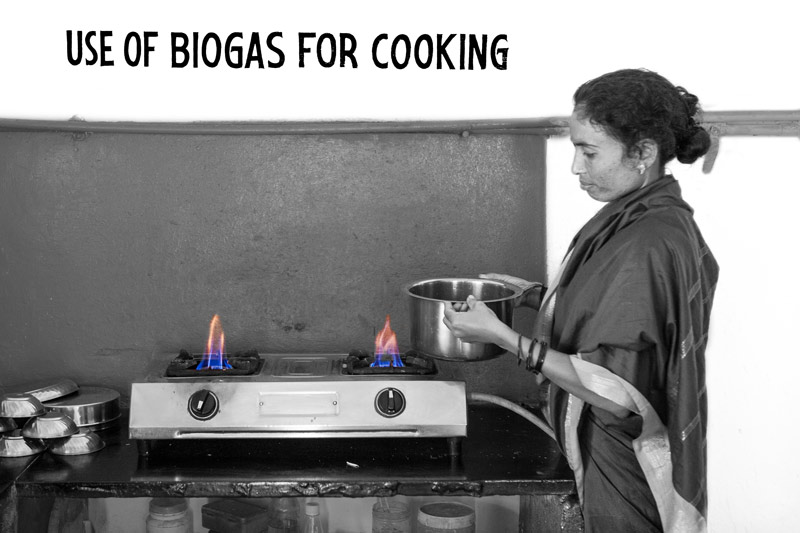

Biogas from the digester being used as cooking gas at the toilet-cum-bath complex in Shirdi, Maharashtra

The biogas generated in the blackwater-based digester can be used as cooking gas, which is the most efficient use of biogas. At the Shirdi complex it is piped directly to the kitchens in the quarters of the toilet caretakers located within the premises. Biogas burners are available in a wide ranging capacity from 8 cft to 100 cft biogas consumption per hour. Biogas burns with a blue flame and without any soot and odor.

A body warming equipment which is lighted using biogas at the toilet-cum-bath complex in Shirdi, Maharashtra

Biogas from the digester can be used for lighting body warming equipment which is very useful during winters. Since it performs the same function as an electrical heater, it can be effectively used in areas having no or poor power supply. Further, unlike the other commonly used non-electrical heaters based on coal or wood, the biogas body warmer does not produce smoke or soot, thus being more user-as well as environment-friendly.

A generator that produces electricity using biogas at the toilet-cum-bath complex in Shirdi, Maharashtra

Biogas can be used for generating electricity in a dual fuel internal combustion (IC) engine. Air mixed with biogas is aspirated into the engine and the mixture is then compressed, raising its temperature to about 350°C, which is the self-ignition temperature of diesel. However, the ignition temperature of biogas is high (600°C). Therefore, in order to initiate combustion of the charge, a small quantity of diesel is injected into the cylinder just before the end of compression. The charge is thus ignited and the process is continued smoothly. At optimum condition only 20% diesel is required, rest (80%) is substituted by biogas. Biogas consumption by the engine is 15 cft/BHP/hour (<0.5 cum/BHP/hour). A public convenience visited by about 2000 persons per day would produce approximately 60 cum of biogas which can run a 10 KVA genset for 8 hours a day, producing 65 units of power.

Garden raised using organic manure derived from the sludge retrieved from digesters at the toilet-cum-bath complex in Shirdi, Maharashtra

The sludge retrieved from the digesters when dried can be used as organic fertilizer in gardens and fields. It is a good fertilizer because it contains nitrogen, potassium, phosphate and other micronutrients. At the Shirdi complex, it is applied to the soil inside the complex to raise a garden.

Treated blackwater being drawn from SET plant attached to the biogas digester at the toilet-cum-bath complex in Shirdi, Maharashtra

In order to make the effluent emerging from the biogas digester free from odor, color and pathogens, it is processed in an effluent treatment plant. Known as the Sulabh effluent treatment (SET) method, the effluent from the outlet chamber of the biogas digester is first lifted into an overhead sedimentation tank and left for one and half hour to settle. It is then passed through a sand filter column and then passed under gravity through activated carbon column where the carbon-contact time is 5-6 minutes. These steps make the effluent colorless, odorless and free from organic particles. Finally it is treated through ultra-violet (UV) column, which eliminates the pathogens. The process reduces Biochemical Oxygen Demand (BOD) of the wastewater drastically from around 200 mg/l to <10 mg/l, making it safe for agriculture, gardening, aquaculture or discharge into any water body. This water can also be used for floor cleaning in toilets and other similar non-potable uses.

Clean recycled blackwater from the SET plant at the toilet-cum-bath complex in Shirdi, Maharashtra

The process of recycling through the SET method renders the wastewater absolutely clean, as can be seen in the photo. While the anaerobic fermentation inside the digester eliminates the pathogens contained in the blackwater by 90-95%, UV radiation in the SET finally destroys any remaining pathogens contained in the emergent recycled wastewater, imparting it a very high quality. The recycled wastewater is colorless, odorless and even safe for direct consumption from the biological perspective.

Recycled blackwater reused for watering garden at the toilet-cum-bath complex in Shirdi, Maharashtra

The decentralized integrated system pioneered by Sulabh is definitely one of the best practices for addressing the challenge of sustainable blackwater management. So far, biogas plants of 35-60 cum capacity have been installed by Sulabh at 200 toilet complexes across the country. Further treatment of the effluent from the biogas plant through the SET method is also available at a number of these complexes. This system is decentralized because blackwater is treated right on-site or closest to where it is generated and collected. It is integrated because it entails treatment of the wastewater as well as the sludge and that its benefits are integrated, generating recycled water for non-potable uses as well as useful byproducts like biogas. On the whole, it offers several advantages over the conventional blackwater treatment systems in use. Being on-site and having capacity tailored to the wastewater volumes generated, it minimizes the risk of contamination of the environment through leakage from damaged long-distance drains or deliberate release of untreated blackwater. Further, the technology is simple, operation and maintenance is easy, and there is no dependence on external energy sources, lack of which otherwise pose significant limitations to efficient operation of STPs in India. Other advantages include the low space requirement – space being a significant limitation in the fast growing cities and towns in the country; generation of biogas – an important energy source in small communities; and liquid and solid organic fertilizers – a sustainable way to restore soil fertility and enhance food production. Also, the life span of the infrastructure is long; cost of installation is low, and de-sludging is required only once every few years. It is also more environmentally friendly by virtue of avoiding greenhouse gas emissions. Given these multifarious benefits, and considering the context of wastewater challenges in the country as described in the earlier photo stories, it is highly desirable that this decentralized model be replicated across urban communities that are not covered by sewage treatment systems. Blackwater management unit consisting of biogas digester of at least 30-60 cum capacity and attached effluent treatment plant can be installed for a cluster of houses having toilets with users numbering 500-5000. The exact number of such units required per colony can be decided in accordance with the number of houses. It would be necessary to maintain segregation of black and grey water in these houses, the latter requiring separate treatment. This practice would enable protection of surface water bodies, groundwater aquifers, soil and the food chain from further contamination, restore lost soil fertility, help maintain green cover, reduce greenhouse gas emissions, and most importantly, drastically reduce the use of already stressed freshwater resources through increased reuse of recycled wastewater. These benefits would in turn support sustainable development in the country and promote human rights of women, men and children to water and sanitation, environment, health, culture and development.